by Inga Meyenborg, translated by Greta Sondej

Fig.: Copyright © ZMorph3D 2019 / Pixabay

Anyone can print out a photo of a whistle at home with a classic inkjet printer. But no sounds can be elicited from this image. That is left to one’s own imagination. To create a three-dimensional, functional product, a different printing process is needed.

Even those who do not follow on engineering and manufacturing techniques have probably heard or read something about “3D printing”. But what exactly does “3D printing” mean?

In technical jargon, this refers to additive manufacturing which contrasts to conventional manufacturing. In the conventional production of components, material is formed or removed. For example, a stainless steel pan can be formed from a flat sheet of metal or a gearwheel can be milled from a solid block of metal.

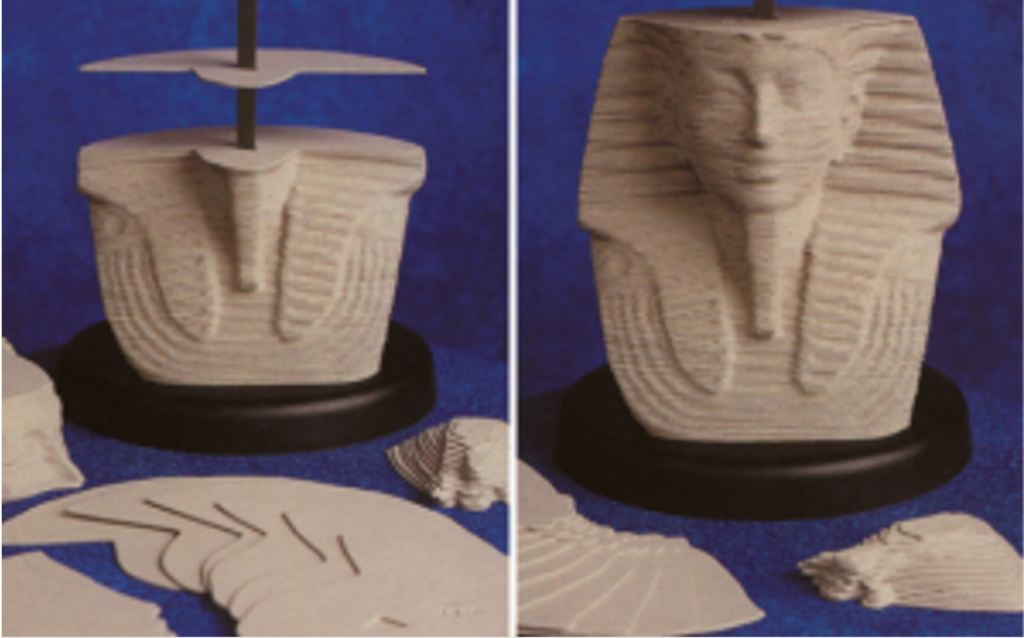

With additive processes, this principle is reversed: The material is built up layer by layer. From the beginning, material is only applied where it is needed. This manufacturing principle is based on the fact that the object to be produced is mentally cut into thin layers. You can imagine this using a sculpture puzzle as shown in Fig. 1, in which a figure is created by stacking many individual sheets about 1.5 mm thick on top of each other.

Fig. 1: Scuplture puzzle from the toy manufacturer Hasbro

Additive processes automate this procedure. They generate the individual layers and add them to each other in the correct order computer-controlled. Thus, only one computer file is needed to provide the information of the desired shape. The generation of these computer files has been established in the industry for a long time. There are various additive manufacturing processes for the layer structure, which differ according to their physical principles for creating the individual layers. One classification differentiates the processes, for example, on the basis of the aggregate state of the starting material. Thus, the layers can be created from a liquid material, such as a resin, or from a solid material, like a powder.

In common usage, the buzzword “3D printing” is used as a generic term for all additive manufacturing processes. However, considering the current standardisation of terms, this is not correct from a technical-systematic point of view [1]. Rather, it is actually only one of many processes, namely the powder bonding process. This process was first mentioned in a patent from the Massachusetts Institute of Technology in 1993. The basic principle of the powder binding process, which is also known as binder jetting, is similar to the procedure of conventional 2D printers, such as the classic inkjet printer. Therefore, the patent introduced the term Three-Dimensional Printing (3D printing) for the powder-binding process.

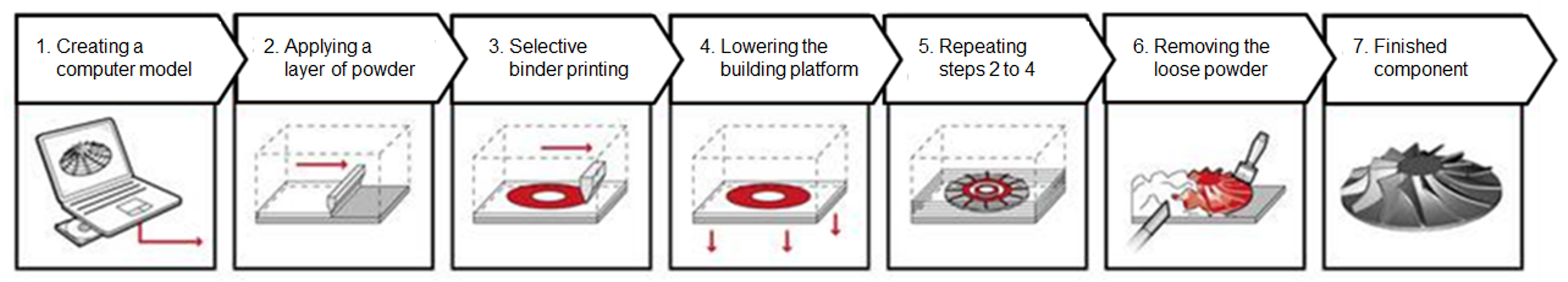

Instead of ink, the powder binding method uses a liquid binder, a type of adhesive. This is not printed on paper but on a thin layer of powder. In this way, the powder particles stick together in the desired places. After the glue has been dried by a lamp, anew layer of powder is applied and the next layer of glue is printed. The mentally sliced component is thus built up layer by layer. At the end, the excess powder can be removed with a vacuum cleaner or brush. Fig. 2 illustrates the process of powder bonding in seven steps.

Fig. 2: Work steps of binder jetting (modified after [2])

With the powder binding process it is possible to work with a wide variety of materials. It is important that the properties of the binder are compatible with the powder. Therefore, there is a wide range of materials to choose from, such as sand, metal powder or even food. For many materials, the strength of the component is sufficient due to the dried binder. In the case of metal powders, however, due to the nature of the material, a further process step is necessary after the component is finished: In the so-called sintering process, the component is heated to a temperature that is between 2/3 and 4/5 of its melting temperature. For ferrous materials, for example, the temperature in the sintering furnace is around 1,200 °C (2,192 °F). This allows the metal powder particles to bond with each other, but the component still retains its shape.

With this process it is then also possible to generate a functional product. Fig. 3 shows an operational whistle produced in one piece using the powder binding process. The ring and the invisible, sound-generating ball inside have already been generated inthe right place during the printing process and did not have to be assembled afterwards. The size comparison with the US penny shows how precise the production can be.

Fig. 3: Whistle made of metal powder, produced in one piece with the powder binding process, for size comparison a US penny [3].

The buzzword “3D printing” will probably continue to prevail in common parlanceas a generic term for all additive manufacturing processes. Nevertheless, it remains to be said that, strictly speaking, this is only the powder bonding process. With this process, it is not only possible to create an effigy, but also, for example, a small functional instrument from many individual layers of metal powder.

If you want to delve deeper into the subject, you will find illustrative information on the individual processes in the standard reference “Additive Fertigungsverfahren: Additive Manufacturing und 3D-Drucken für Prototyping – Tooling – Produktion” by Andreas Gebhardt published by Hanser publishing house.

At the University of Bremen, research into the powder binding process is taking place at Fraunhofer IFAM, for example [4].

References:

[1] Verein Deutscher Ingenieure (Association of German Engineers), „VDI-Richtlinie: VDI 3405 Additive Fertigungsverfahren – Grundlagen, Begriffe, Verfahrensbeschreibungen“. Dez-2014.

[1] A. Gebhardt, Generative Fertigungsverfahren: additive Manufacturing und 3D-Drucken für Prototyping – Tooling – Produktion, 5., Newly revised and expanded edition. München: Hanser, 2016.

[2] Davidvx, English: 3D-Printingprocess. 2015.

[3] Fabbaloo, „Who Is Höganäs and How Did They Make This Amazing Metal 3D Printer?“, Fabbaloo. [Online]. Available via: http://www.fabbaloo.com/blog/2016/7/7/who-is-hgans-and-how-did-they-make-this-amazing-metal-3d-printer. [Last access: 07-Feb-2018].

[4] „Additive Manufacturing – Fraunhofer IFAM“, Fraunhofer-Institut für Fertigungstechnik und Angewandte Materialforschung IFAM. [Online]. Available via: https://www.ifam.fraunhofer.de/de/Forschung/additive_manufacturing.html. [Last access: 14-Feb-2018].

Cover picture: Pixabay, Copyright © ZMorph3D 2019, URL: https://pixabay.com/de/photos/drucker-technologie-3d-drucker-4348150/ [latest visit: 11/28/2021]

Leave a Reply