The 2nd transfer seminar on updating work of the partners and the exchange of ideas was held on the 12th to 14th September 2022. It was held at the University of Bremen at the Faculty of Electrical Engineering and the Maritime Business and Logistics Center. The seminar was separated into two parts where first part was on updating work done on the NAVEL proptotype and the presentation of the FabLab of the Communication Networks Work Group. The second part was on the discussions held between the Maritime Business and Logistics Center and the participants of the University of Ngaoundéré on the topic of the Logistics Innovation Center Ngaoundéré.

The agenda of the 1st part of the seminar was as follows.

- Introduction – Anna Förster

- NAVEL Update – Anna Förster, Asanga Udugama

- NAVEL Prototype

- Documentation and Training Material

- ComNets Fab Lab Tour Jens Dede, Eenesh Chavan, Christina Stålhammar

- General Introduction

- Some prototypes developed at the Lab

At the seminar, the idea behind the prototype was presented and discussed in detail. The general idea is summarized below.

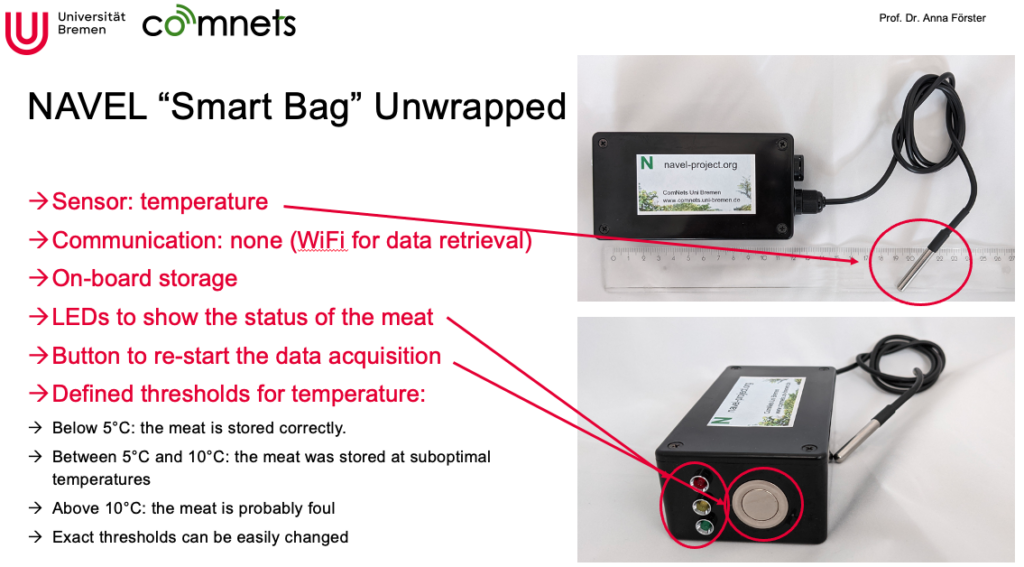

- Idea of the prototype

- Device, which monitors the temperature of a bag/container/parcel

- Compares the temperature to optimal values, e.g. 5°C.

- If the temperature was exceeded for more than X minutes, then a lamp (LED) should go on

- The receiver of the parcel can check the device and know whether the temperature was exceeded during the transport

- No communication required (no cost for SIM cards, access points or usage)

- Cannot be tracked in real-time

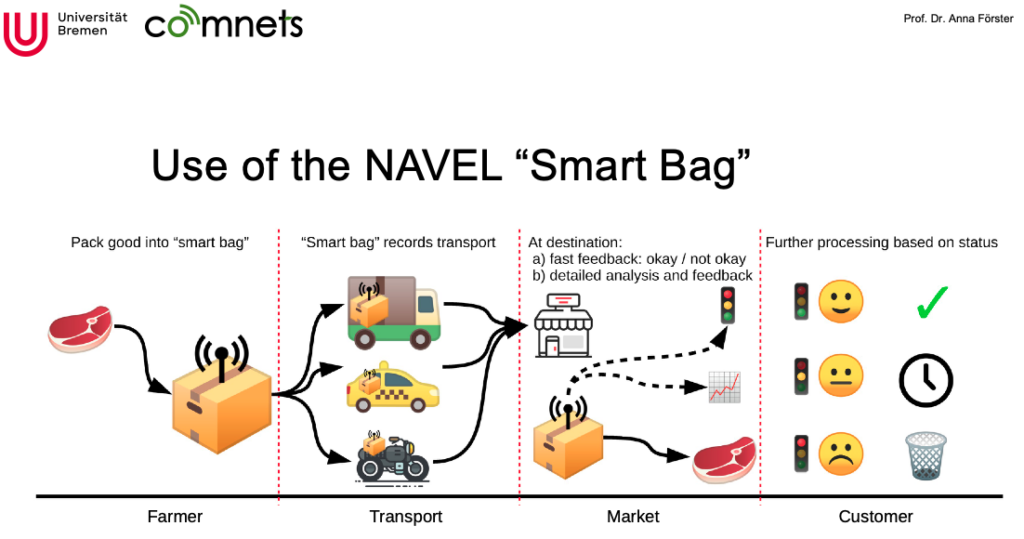

The basic points, listed above were implemented based on the use case depicted in the following picture. We refer to this solution as the NAVEL “Smart Bag” as it is usable in any context where such a measurement device is required. In the NAVEL project, we also consider milk in addition to meat. In the case of milk, the “Smart Bag” may be a container holding the milk.

The device, i.e., the “Smart Bag” solution built is shown in the next picture, detailing the constituent parts.

The device was programmed to performed the work as depicted in the above use case. The code of the device is publicly available for any party, especially the users of the Fab Lab in Ngaoundéré to use in finding similar solutions for logistics problems they face when transporting goods. The link below provides the link to the code at GitHub.

Code of the Smart Bag Prototype

Additionally, we have developed training material that is useful for the users of the Fab Lab, detailing how the available resources such as microcontrollers, sensors, etc. can be used to develop solutions to logistic problems. The training material is available at the following GitHub link.

NAVEL Fab Lab Training Material

Since the meeting couldn’t take place in person, according the COVID Pandemic, the objectives of the second part of the meeting were about at the personal interaction, exchange and discussion. For this purpose, the results of the analyses of the milk and meat supply chains were presented and discussed in the second part of the event. The presentations highlighted the Status-Quo, as well as the challenges in the milk and meat supply chain, so the suitability of tracing tools, like the “Smart-Bag” can be discussed. Furthermore, the students have the chance to discuss their preliminary results face to face with Prof. Tsapi and his colleges. The meeting was following the following schedule:

- Introduction – Hans-Dietrich Haasis

- Presentation of the Meat Supply Chain – Marie Noël Assene

- Presentation of the Milk Supply Chain – Nadège Ingrid Gouanlong Kamgang

- Presentation of the students results in the Master project “Milk Supply Chain”

Next to the meeting Prof. Tsapi was officially welcomed by the Chamber of Commerce on Friday morning.